Whether it is an insulated power cable or other types of cables, it may malfunction due to man-made or natural reasons during use. After a fault occurs, the copper conductor power cable fault should be handled as soon as possible to ensure normal power transmission. At the same time, it is understood that more than 80% of ac aluminum power cable accidents are caused by improper operation and improper laying.

Here is the content list:

- What are the reasons for power cable in need of repairing?

- How to repair power cable in different situations?

- How to reduce the accident rate of power cable from the source?

What are the reasons for power cable in need of repairing?

In the process of long-term use, the power cable is constantly subjected to the thermal, chemical and mechanical effects brought about by the electrical action. At the same time, power cable accidents have a seasonal tend.

In fact, they are likely to be concentrated in the second and third quarters, and low-voltage power cable accidents are much higher than those of high-voltage ones. The main reasons for so many personal and property casualties are as follows:

· Poor quality

If the power cable is a low-quality product, the middle joint or terminal head may be damp due to the upper and lower sealing of the structure or poor installation quality. When manufacturing the power cable insulation layer, leaving defects such as blisters or cracks will also lead to failure.

· Overheat

There exist various possibilities for power cable overheating. The internal cause is the free internal air gap of the insulation, causing local overheat and carbonization of the insulation.

The external cause is that power cables are intensively installed or installed in areas that cannot be effectively ventilated, and the insulation will be damaged due to overload or poor heat dissipation of the cable.

· Mechanical damage

This kind of damage of power cable is mainly caused by external force. This is mainly due to the mechanical action of construction activities, which deforms the power cable, which leads to excessive bending and damages the internal insulation.

· Chemical damage

Due to electrolysis or chemical action, the protective layer of the power cable is corroded. Depending on the nature and degree of corrosion, red, yellow, orange and light-yellow compounds or sponge-like pores may appear in the metal power cable protective layer.

How to repair power cable in different situations?

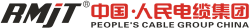

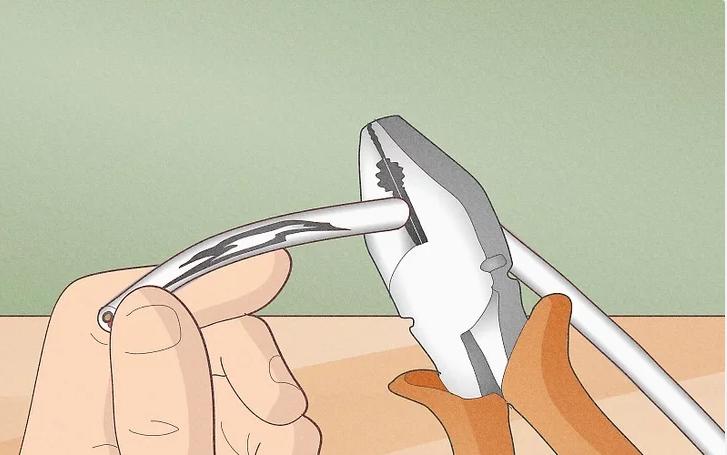

When the power cable is dented, broken, or cracked, the defective part should be cut into a slope with a 45° angle with a knife, and then use materials of the same color and thickness to maintain the patch, and then use hot welding machine to fix.

After completing this series of procedures, in order to test the results of the power cable fault handling, you need to do a test with a spark machine. If the protective layer is not broken down by the spark machine, the fault repair is successful.

If the power cable has collapsed holes and other faults, it should be handled in the same way as above. It is also to fill in the faulty place and weld it, and then test whether it can be broken down with a spark machine.

If the power cable has faults such as wrinkles and bulges, you can first use a knife to smooth the defect, then use the same material and color to fill the defect, and use a hot air plastic welding gun to weld it. Use a copper sheet to flatten the defect.

How to reduce the accident rate of power cable from the source?

We can find that in many power cable accidents, the failed power cable has problems with the design and manufacturing process of the intermediate joint and the terminal head.

This may be caused by the production process of power cable. For example, when the semiconductor is peeled off, the internal insulation is damaged, or there are particles, dust and other impurities on the surface of the insulation; poor sealing of the power cable head makes the water get into the insulation, causing the insulation to be damp.

What's more, the power cable joint process can be not standard, and the sealing is not standardized, which causes wrong grounding; high humidity in the production environment will cause the power cable insulation to become damp as a whole; cable grounding errors will cause the grounding wire to form a circulation or break.

Therefore, in order to avoid power cable failure from the source, consumers must choose a responsible and qualified power cable manufacturer. Although high-quality power cable may have a higher price than inferior ones, its super high cost-performance is worth the price.

We hope that consumers can correctly evaluate the cost performance of ac aluminum power cable, and then choose the right product. People’s Cable Group Co., Ltd. provides copper conductor power cables with multiple quality certifications to ensure the smooth progress of industrial production activities and better realize the safety of ac aluminum power cable power grids. If you need other types of cables, you can also find them in our product list.