High strength

Large current carrying capacity

Good catenary property and wear-resistance

Anti-crush and corrosion-proof with simple structure

This cable is used to transmit power on the power transmission and distribution line of A.C.50Hz, rated voltage 36kV or lower. They are suitable for installations indoors: mostly in power supply stations and outdoors: in cable ducts, underground, and on cable trays for industries, switch-boards and power stations.

IEC60502-2 Power cables with extruded insulation and their accessories for rated voltages from 1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV)

Part 2: Cables for rated voltages from 6 kV (Um = 7,2 kV) up to 30 kV (Um = 36 kV)

Rated Voltage:

● 3.6/6 (7.2) kV

● 6.0/10(12) kV

● 8.7/15(17.5) kV

● 12/20(24) kV

● 18/30(36) kV

The ambient temperature for cable installation :≥0 0C

This minimum working temperature of the cable is -20 0C

This maximum working temperature of the conductor is 90 0C;

During having a short (lasting less than 5 seconds) the maximum temperature of the cable conductor shall not be above 250 0C;

Bending radius allowance of the cable:

| Type of cable | Minimum Bending Radius (mm) | |

| During Installation | Adjacent to joints or terminals | |

| Single Core Cables | 15D | 12D |

| Three Core Cables | 12D | 10D |

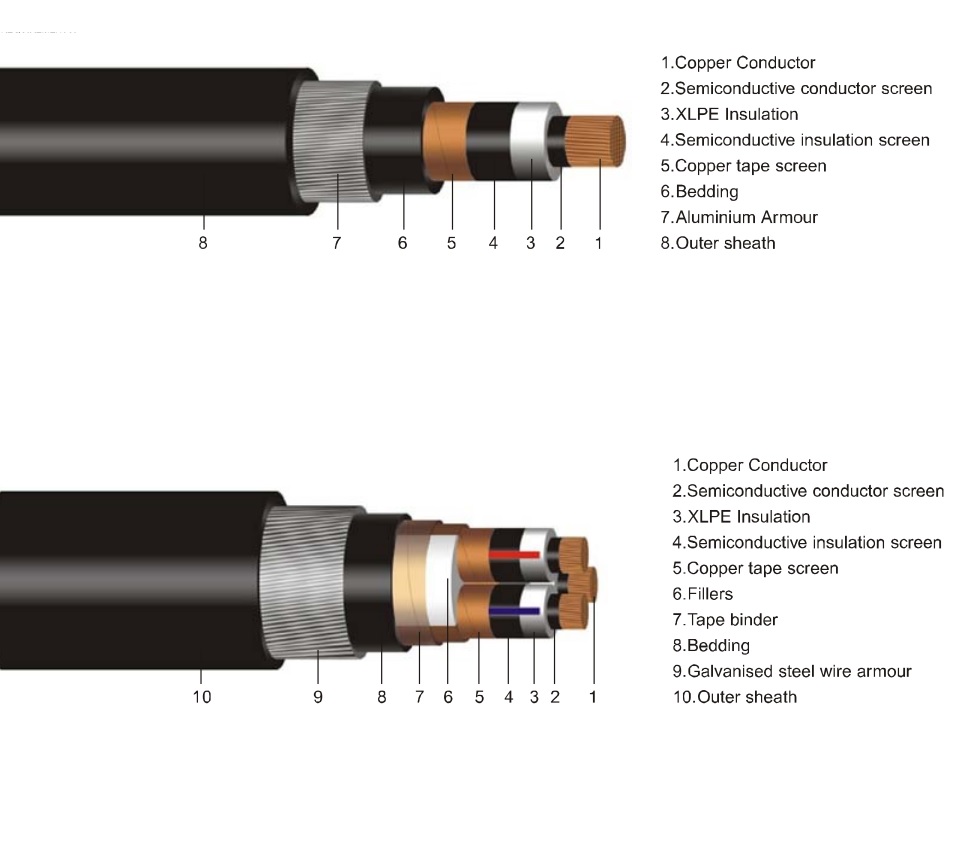

Conductor

Class 2 stranded circular or circular compacted

Semi-Conductive Layer for Conductor

Semi-conductive material

Insulation

XLPE (Cross-Linked Polyethylene)

Semi-Conductive Layer for Insulation

Semi-conductive material

Metallic screen

Copper wires / Copper Tape / Copper Wire & Tape

Inner Sheath

PVC (Polyvinyl Chloride)

Amoured

STA- Steel Tape Amoured

Non-magnetic amoured material used for single core cable.

Outer Sheath

PVC (Polyvinyl Chloride)

The conductor Semi-Conductive Layer, XLPE insulation and the insulation Semi-Conductive Layer are extruded simultaneously in one process using triple extrusion method (Continuous Vulcanization Line). Triple extrusion method not only assures clean interfaces between the insulation and stress control layers, but also assures a construction free of Partial Discharge with high operational reliability.

The Main Technical Parameter Of The Cable

1) Cable conductor DC resistance: See the table 1-1

2) Partial discharge test: See the table 1-2

3) AC voltage test: See the table 1-3

4) Rated Voltage,Core Numbers & Nominal Cross-section Area : See the table1-4

Table 1-1 Max. DC resistance of cable conductor at 20 0C

| Rated cross area (mm2) | 16 | 25 | 35 | 50 | 70 | 95 | 120 | 150 | |

| Cu (Ω/km) | Non tinned | 1.15 | 0.727 | 0.524 | 0.387 | 0.268 | 0.193 | 0.153 | 0.124 |

| Tinned | 1.16 | 0.734 | 0.529 | 0.391 | 0.270 | 0.195 | 0.154 | 0.126 | |

| Al (Ω/km) | 1.91 | 1.20 | 0.868 | 0.641 | 0.443 | 0.320 | 0.253 | 0.206 | |

| Rated cross area (mm2) | 185 | 240 | 300 | 400 | 500 | 630 | 800 | 1000 | |

| Cu (Ω/km) | Non tinned | 0.0991 | 0.0754 | 0.0601 | 0.0470 | 0.0366 | 0.0283 | 0.0221 | 0.0176 |

| Tinned | 0.100 | 0.0762 | 0.0607 | 0.0475 | 0.0369 | 0.0286 | 0.0224 | 0.0177 | |

| Al ( Ω/km) | 0.164 | 0.125 | 0.100 | 0.0778 | 0.0605 | 0.0469 | 0.0367 | 0.0291 | |

| Rated Voltage (kV) | 3.6/6 | 6/6 6/10 | 8.7/10 8.7/15 | 12/20 | 18/30 | 21/35 | 26/35 |

| Test Voltage (kV) | 6.23 | 10.38 | 15.05 | 20.76 | 31.14 | 36.33 | 44.98 |

| Discharge capacity (pC) | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Rated Voltage kV | 3.6/6 3.6/10 | 6/6 6/10 | 8.7/10 8.7/15 | 12/20 | 18/30 | 21/35 | 26/35 |

| Test Voltage kV | 12.5 | 21 | 30.5 | 42 | 63 | 73.5 | 91 |

| Test Time min | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| U0/Um Area mm2 | 3.6/6 | 6/6 6/10 | 8.7/10 8.7/15 | 12/20 | 18/20 18/30 | 21/35 | 26/35 | |

| Core No. | 1 | 25-630 | 25-630 | 35-630 | 35-630 | 50-630 | 50-630 | 50-630 |

| 3 | 25-400 | 25-400 | 35-400 | 35-400 | 50-400 | 50-400 | 50-400 | |

Our professional team will reply you as soon as possible.